Water Divining: Myths and Beliefs

Divining and Water Bores: Divining –Myth or Actual. Barry is a believer in divining and has performed divining with proven success over many years, Particularly in the hills areas of Perth and regional areas where we specialise in hard rock water boring. We pride ourselves in this unique service of “ Water Divining” and are Specialists in drilling on narrow hard rock and limestone streams throughout the hills of Perth and surrounding areas.

Examples of Divining success

(1) 5 acre property in Bullsbrook .

Three water bores were drilled by a contractor with small rig unable to penetrate granite. Total water flow from 3 bores- 500 ltrs per day. The property was later divined by Barry, a suitable location found, one hole drilled into granite. Total depth 48m- developed at 1500ltr per hour.

(2) 60 acre property Bindoon. Two bores drilled by the contractor, one x 100m, other 60m, both were dusters. Divined and drilled on new location approx 20 metres from one of the bores . At 42m hit the divined fracture with water flow at 1250 ltr hr.

And there is much more success.

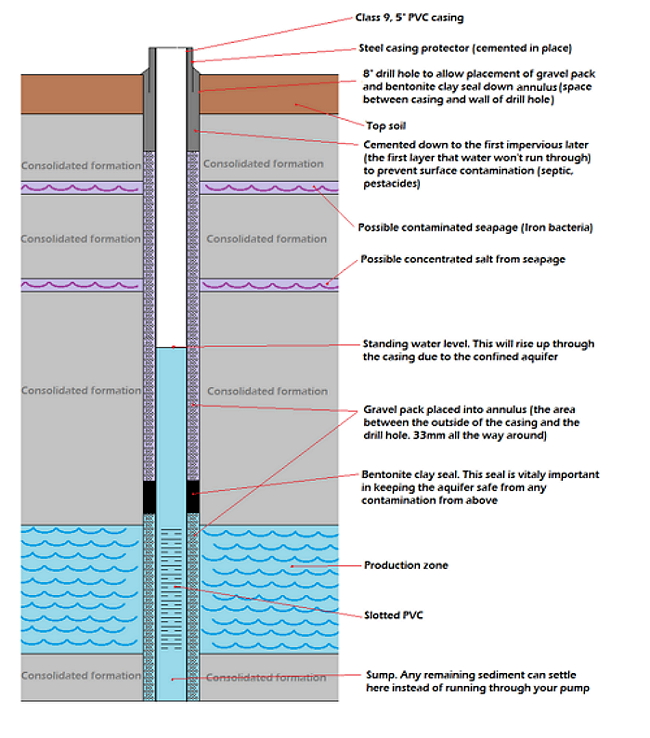

There are three main kinds of underground water sources, Streams, Superficial Aquafers, Confined aquafers. Surficial aquafers are common and generally shallow in depth 5m-80m and is common for the Perth area sand plains and are used by common household for residential/domestic purposes. The Confined aquafers are generally deeper and between 100m to 500m and the water here is used for commercial purposes. Streams are more common to the hills areas and are generally 10- 100m in depth and are fractures in the granites or old gravel beds from ancient streams which water flows through. Drilling a Hole for Water without Divining can become a non- productive very expensive option. Divining for a water stream prior to drilling a hole is highly recommended particularly throughout the hills areas and regional areas . Even in Coastal Zones like areas Gingin to Lancelin. Once a potential location has been divined then the drill can commence to drill the hole to the source. In the Hills surrounding Perth the ground can be very hard to drill which requires a reasonable heavy duty percussion drill.